QuinLED-Dig-Uno Pinout Guide

QuinLED-Dig-Uno v3 / v3.1

If you are looking for the QuinLED-Dig-Uno v2 pinout guide, please go here

The GPIO_ESP32 number is what you use in WLED!

| GPIO_8266 | GPIO_ESP32 | Board | Use |

|---|---|---|---|

| A0 (A0) | A0 (SVP) (IO36) | A0 | Analog Audio Pin |

| N/A | GPIO_0 | Button | WLED Button (is pulled high) |

| N/A | GPIO15 | Q1 | External GPIO (can be pulled low) |

| N/A | GPIO12 | Q2 | External GPIO (can be pulled low) |

| N/A | GPIO_2 | Q3 | External GPIO (can be pulled high) |

| N/A | GPIO32 | Q4 | External GPIO (can be pulled high) |

| N/A | GPIO13 | DS18B20 | Onboard Tempsensor |

| RX (IO3) | GPIO16 / GPIO_1 | LED1 | LED1 output (*Jumper selectable) |

| TX (IO1) | GPIO_3 | LED2 | LED2 output |

LED1 and LED2 are only usable as outputs since the Level Shifter is unidirectional. The Dedicated GPIO’s are usable as inputs or outputs.

Pinout guide assumes you are using a QuinLED-ESP32, if using D1 Mini32 GPIO1 and GPIO3 can be reversed!

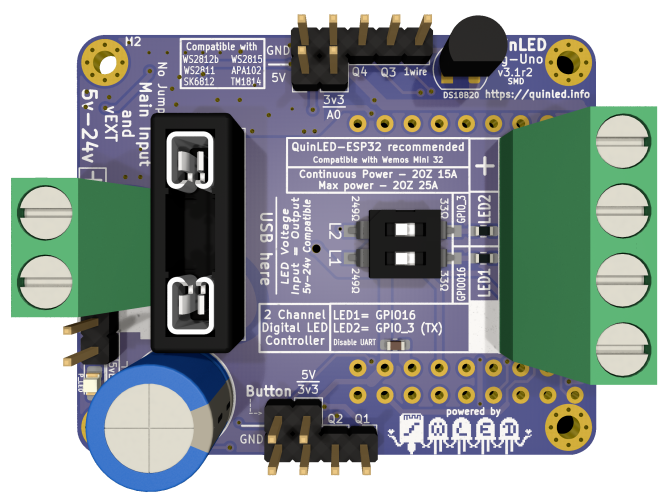

Board Pin Locations

To find the corresponding pins on the board please see the following graphical image:

Bonus configuration

Although the QuinLED-Dig-Uno name clearly infers that it’s a single channel controller, using the ESP32 it’s actually possible to use 2 clockless (WS2812B, WS2815, sk6812, etc.) LED strips with this board! Both the LED1 and LED2 are run through the level shifter independently, so there is no downsides to doing this! Make sure not to exceed total board power limits though.

Wiring Guide

Wiring LED strip seems simple but becomes more complex the longer the length becomes. The QuinLED-Dig-Uno has been designed for small to medium sized installations. It does this by allowing you to run a pretty high amount of current through the board. For power injection you will have to use an external solution such as WAGO clamps, but the onboard fuse will still protect you. If you need more power injection, stepping up to the QuinLED-Dig-Quad is advised.

The board is 5v, 12v and 24v compatible. Although this doesn’t make a difference in wiring it up it can make a difference in designing your LED install. Generally speaking 12v or 24v Digital LED strip can be run in longer lengths and with more LEDs without suffering as much voltage drop as their 5v counter parts but the downside is that these are generally per 3 or per 6 addressable instead of per 1 for 5v.

Make sure to check out the wire thickness needed page to determine what thickness cable you require for your desired lengths and application! Also remember to provide proper cooling for your LED strip although with Digital LED strip it is very dependent on what is going to be displayed, random color don’t generate too much heat but sustained white output will quickly burn up your LEDs!

Digital DATA Signal

Different from analog LED strips, digital LED strips have a positive and negative rail but also need a data signal (or sometimes a data and clocks signal) to work. While power can travel both ways (and is intended to be used that way with power injection), the data and clock signals can only follow the arrows on the strip and thus are uni-directional. You don’t have to worry about data or clock signals degrading on the LED strip itself because they are boosted by each LED (pixel/package) to the next one (max 1 meter). The data signal from the controller is much stronger and will generally be ok for 5m to 10m.

When soldering on your wires or applying the strip in it’s final destination, check that the arrow is pointing in the right direction!

Wiring Diagrams

For the suggested wiring diagrams for the QuinLED-Dig-Uno, please see this article.