QuinLED-Dig-Octa

Power-7HC

Power Handling

When dealing with up to 100Amps of continuous power delivery there are absolutely some rules we need to follow to make sure all this power flows correctly. The below values are actual real-world tested values. There are a lot of power distribution and fusing boards out there but most are not designed to actually run their rated loads or only do so while dropping a lot of voltage which in turns results in extra heat being generated. Especially for 5v application it’s important the power distribution happens as efficiently as possible.

Maximum current and fuses

- Total power continuous (5v, 12v or 24v) = 100Amps

- 5v = 500w

- 12v = 1200w

- 24v = 2400w

- Maximum fuse for a single input terminal = 60Amps

- Maximum fuse for a single output terminal = 10Amps

- 5v = 50w

- 12v = 120w

- 24v = 240w

Maximum cables sizes supported

- Input M5 bare terminal

- Using the right kind of fork, ring or lug crimp up to 6AWG/13.3mm2 is supported

- Output 7.62mm screw terminals

- With wire ferrule a maximum cable of 12AWG/3.3mm2 is supported

- Using special “double up” feature up to 6AWG/13.3mm2 is supported

Input cabling

To support up to 100Amps of power with as little voltage drop as possible the power-7HC has 2x M5 bare terminals. These large input terminals can accommodate very large cables easily and are generally used with fork or ring crimps with up to 6AWG/13.3mm2 cable coming from the same power supply.

As noted on the board each input is rated for max 60Amps thus if you wish to use the full 100Amps capability of the board you will need to hook up all 2 input terminals (both for positive and negative) from the same power supply.

! Using fewer input cables lowers total board current capabilities

Suggested input cable thickness

To minimize voltage drop it’s recommended to use at least 2x 10AWG/5.2mm2 cables from the power supply finished with fork style crimps.

Especially for 5v applications even preventing the smallest amount of voltage drop at this point in the setup is advisable so using 8AWG/8.3mm2 or 6AWG/13.3mm2 is preferred. For 12v and 24v this is a bit less important since although the amount of voltage drop will be the same, percentually it’s less because of the higher voltage.

To learn more about sizing your power wires, please see the following article.

! Using thinner cables then suggested will cause more heat and voltage drop!

Total fuses and rated continuous load

As can be seen above the board can have 16x 10Amp output fuses bringing the total amount of current to 160Amps total but the total continuous rated power however is “only” 100Amps.

While designing your setup you need to take this into account but also please read the following:

Especially with LEDs we’re dealing with very varying or high transient power demands. At one point total power draw might be 60Amps while a few seconds later 120Amps might be drawn. As long as these are peaks and continuous load remains at or below 100Amps generally it’s fine to use the board like this.

*I recommend using the 50% RGB white values from my power sheets to calculate nominal load

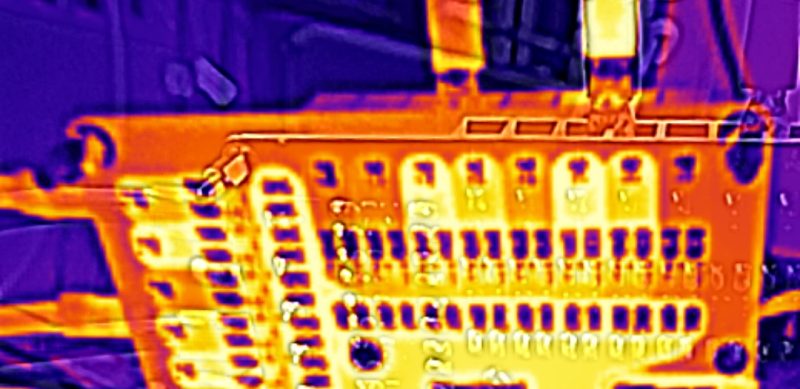

The main reason for the power rating is heat, the more current passes through the board the higher the amount of resistance and thus heat that will be generated within the copper planes and fuses on the board. The boards have been designed to only increase ~25c above ambient when running 100Amps of current through them. In a 25c room that means that the board at it’s hottest point will become 50c. So in a scenario with a widely varying load having big spikes and then lower falls in power demand is perfectly fine as long as the average doesn’t exceed the rated 100Amps.

Suggested Power Supplies

There is a dedicated article talking about suggested power supplies (with or without fan) for your 5v, 12v or 24v project.

Spreading the heat

One thing to take into account when designing your setup is to spread out the potential heat where possible. In designing a system I often speak about edge connections and middle connections with LED strips or LED pixel strings. Roughly speaking an edge connection will draw about 4Amps maximum and a middle connection double that.

When wiring these up to your powerboard try and spread out the high current demand wires over the board with low or medium current demand cables in between. This will allow for the best usage of the power planes on the board (lowering voltage drop) and also spreading out the heat to a larger area keeping the board cooler.