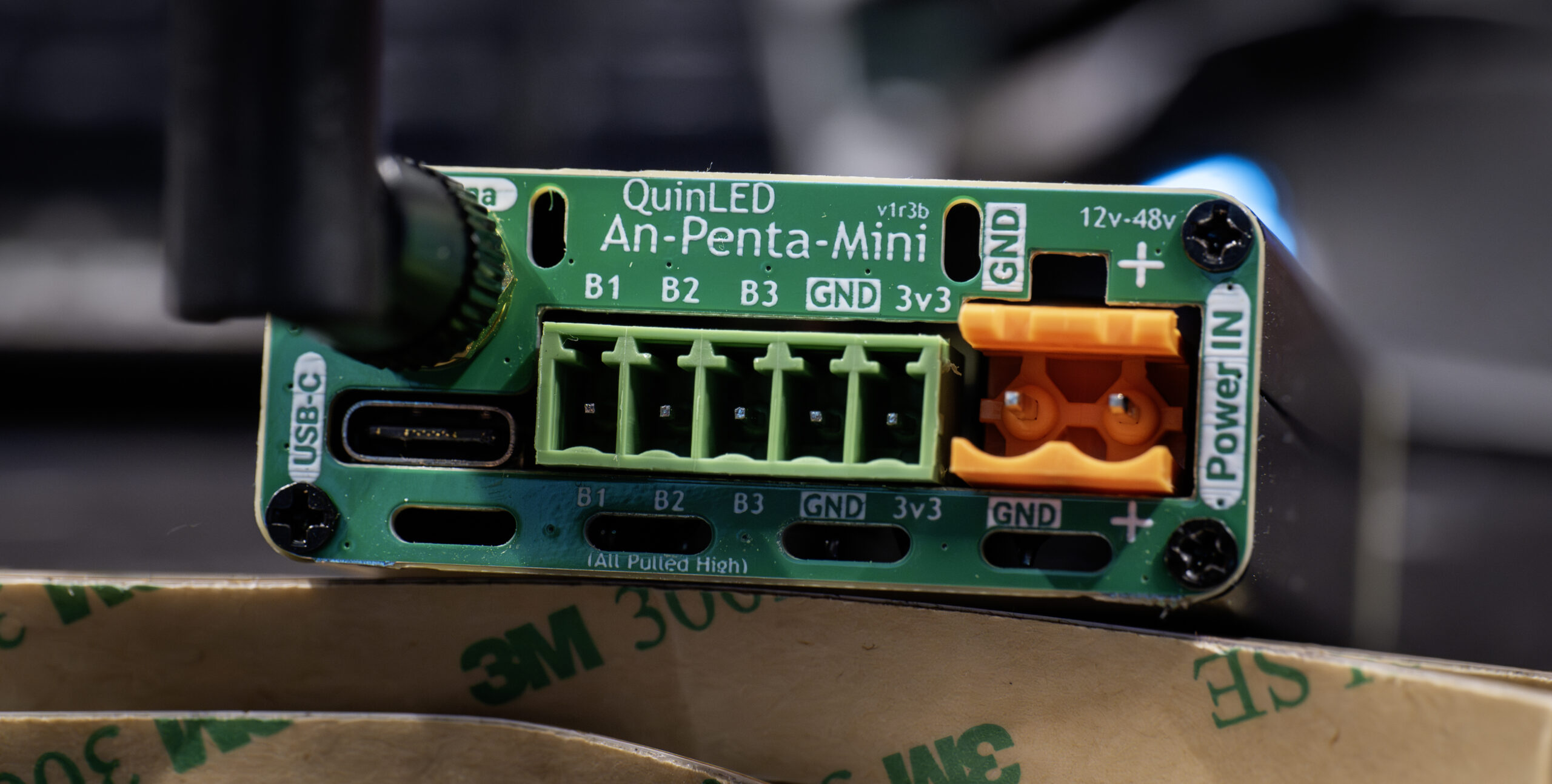

QuinLED An-Penta boards running hot!?

Back to QuinLED An-Penta-Mini Index

You might have noticed that if you have one of the QuinLED An-Penta boards that these are running a bit warmer or even close to hot vs other Analog dimmer boards you might have used before. This articles will serve as a bit of an explanation as to why this is the case (hehe, pun intended) and if it’s something to worry about or not.

Primary reason: Fuses

One of the unique selling features of the QuinLED An-Penta lineup of analog PWM dimmers is that they include fused positive outputs. But because of this feature there will be more heat generated vs controllers that don’t have this protection feature built-in.

The reason for this is how fuses work, most type of fuses work by a thermal resistance that increases up to a point where the wire that’s inside, that the current is running through, breaks and thus disconnects the load. This means that a fuse will have a set amount of resistance and if you combine resistance with current you have a by-product that is well, heat. And thus adding fuses to any product will make it run warmer then a product that doesn’t have it.

Your other products have fuses?

Yes that’s true but these products are generally not enclosed in a small enclosure (exception being the dig2go). All boards have been designed with thermals in mind and to spread heat out to an as large an area as possible and with the boards being exposed to air, even if they are inside of a larger controller box, this means that the heat can easily be dissipated and you don’t really notice this effect too much.

For more about the fuses used and how to replace them, please see the following article. [article about SMD fuses]

Secondary reason: Boards are housed in a metal enclosure

The QuinLED An-Penta lineup of boards all come deliver in a metal (aluminium) enclosure, that means that the boards transfer the heat to the air and partially to the enclosure directly, heating these up in the process. They don’t necessarily serve as a heatsink (they aren’t used to cool a component or the boards) but they do have the function of being a heat spreader. This means that when you touch or pick-up the controller it will feel warm or even slightly hot to the touch! We’re not talking scorching temperatures though, nothing to hurt you but you might still be surprised that it’s so warm.

Added venting holes

If you look closely at some of the photos in the articles of the QuinLED An-Penta-Mini you’ll notice that there are the nice looking black front and end plates but also some green holes. These were a last prototype during production and have added “speed holes” as I call them, but they are basically venting holes for the top and bottom portion inside of the enclosure to promote any kind of airflow there might be there. This helps keep the enclosures a little bit cooler!

Third reason: MOSFETs

Although great care has been taken in selecting the MOSFETs (brand/type) and (especially on the bigger boards) they are driven with high voltage gate driver circuits, MOSFETs will still generate a bit of heat.

But, the QuinLED An-Penta controllers also allow you to choose the PWM frequency you wish to run at, and because of switching losses, the MOSFETs will heat up more with higher frequenties.

MOSFET switching losses

Basically a MOSFET is very efficient when it’s off or on, in between is not and generates heat.

In short, if you switch the MOSFET on/off 10 times a second and each switch generates say 0.1w of heat, that means you are generating 1w of heat. Now starting switching it 100 times a second, this means that in theory 10 times as much heat is created since each switch still generates the same amount of heat and thus you are now generating 10w of heat.

Now this is a very rudimentary explanation of what is happening and the amount of heat being generated is nowhere near 1w or something like that, but it’s just to explain the point. If you are running the channels at 1kHz the MOSFET physically will stay much cooler then running at say 120kHz. The boards are designed around a target of ~20kHz but as said can run much higher although you might have to downrate the outputs a little bit because of that, but this is mentioned per board in the power handling articles.

Fourth reason: Plugs and wires getting warm

When you running things near their maximum things will start to heat up. The pluggable connectors I’ve used on these controllers do great up to about 5A but above that they start to show a bit more losses then non-pluggable variants. Especially on the QuinLED An-Penta-Mini you will see this on the input side where you can go up to 10A of current. The biggest boards have different pluggable terminals which can handle such high loads a bit better. Still, this also adds heat into the controller, make sure to use the largest wire diameter you can when feeding the board (14AWG for instance).

Next to the pluggable connector heating up, depending on the wire diameters used the wires themselves will also heat up, especially the generally thing wires connected to the LED strips and if you are running them with a high load. This heat will also partially make it back into the board and enclosure. This isn’t a problem, just a contributing factor for things heating up a bit.

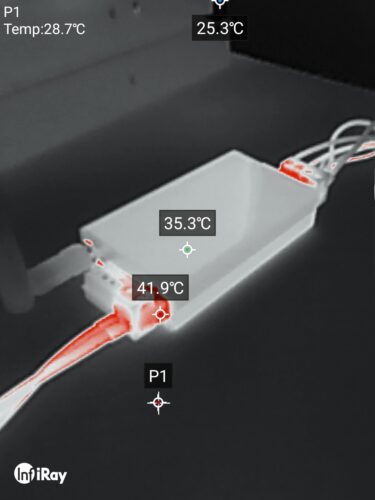

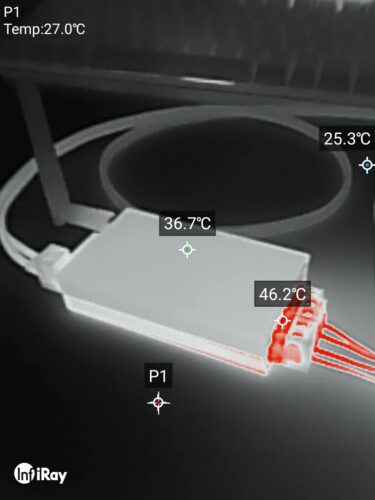

Running at max output of 2x 5A (@24v so 240w)

Running at max output of 2x 5A (@24v so 240w)

Conclusion, something to worry about?

Hopefully this helps explain why the QuinLED An-Penta boards controllers might run a bit warmer then you would have expected. Especially if you touch the enclosure when you are running 50% or more of their rated output, they will certainly feel warm but this is by design, even if the enclosures approach 50c running them near 100%!

The boards, components and chips are all rated to run these temperatures and having been spaced accordingly on the PCB. All capacitors are 105c rated and while that doesn’t mean you want to run them (near) that temperature, it should still ensure a long life-time even when running a lot of current through the boards.

The QuinLED An-Mini with the ESP32-C3 has a built-in temperature sensor in the ESP32-C3 chip that you can enable for the other 2 boards you will have to add my “QuinLED-I2C-Temperature” sensor board, at the time of writing this has not been released yet.