Barrier terminals on QuinLED boards

TL;DR Recommended fork crimps for my boards!

Video about which type of cables and connections for all QuinLED-Dig boards

Text article about fork crimps

The more your LED setup grows the more power you need so naturally also the thicker your wires need to be. In this article we’re specifically talking about the input wires from the power supply to your QuinLED board.

Normally we use standard wire but those can be difficult to deal with so often we terminate these wires using wire ferrules. But, as sizes increase, using a different type of connection is preferred to transfer the increasing amount of current and handle the thicker size wires.

On my boards that carry more current (Basically above the Dig-Uno so the QuinLED-Dig-Quad, QuinLED-Dig-Octa System Power-5/Power-7) I started integrating M4 size barrier style terminals. On the QuinLED-Dig-Octa System Power-7HC I even upgraded that to large high-current M5 terminals to allow up to 100Amp continuous through the board!

But if you can’t use a wire ferrule, what kind of crimp or wire termination is best suited for these terminals?

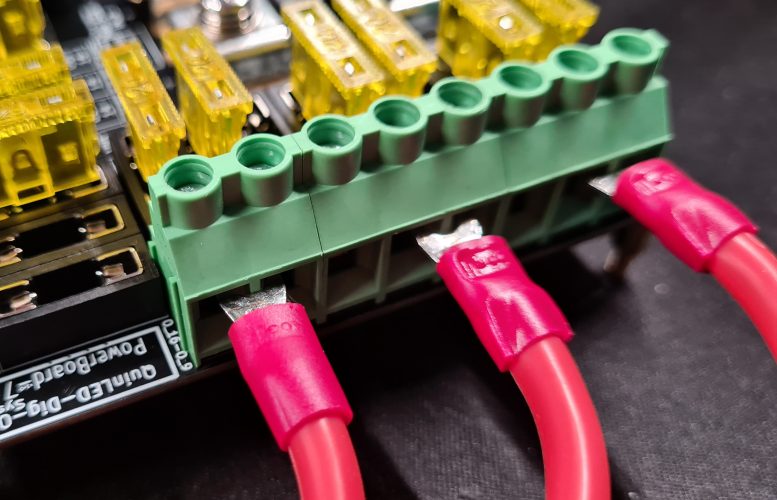

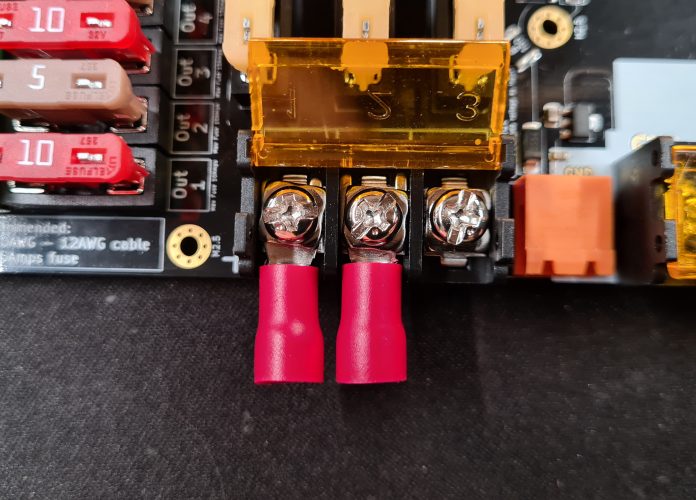

(Left) SV5.5-4 (perfect), (Right) SV5.5-5 (fits but slightly too big) in a M4 barrier style terminal block

(Left) SV5.5-4 (perfect), (Right) SV5.5-5 (fits but slightly too big) in a M4 barrier style terminal block

Fork style crimps

I like using fork style crimps for barrier terminals, these form a really secure and good connection once screwed down. They also have much more surface area connected between the cable and terminal then for instance a wire ferrule so make for a lower resistance connection.

Fork crimps can be bought in various sizes which can make it a bit confusing, this article will explain what you need for the QuinLED boards which accept these.

Recommended cable size for barrier style terminals

For most of my boards using the bigger barrier style terminals I recommend using at least 12AWG (3.3mm2) cable up to 10AWG (5.2mm2) cables to connect the board to your power supply. This will ensure as little as possible voltage drop as possible but it’s always good practice to calculate the wire diameter you need.

Which fork style crimps to get for that?

For the barrier style terminals that are on most of my boards on the input side I recommend SV5.5-4 crimps. For the Power-7HC I recommend getting SV5.5-5 crimps (or bigger with a crimped lug!).

*Tip: Meanwell power supplies such as the LRS or UHP series also use M4 barrier terminals and fit the same SV5.5-4 crimp perfectly!

The 5.5-4(S) and 5.5-5 accept the same size cable but have a differently spaced fork!

The 5.5-4(S) and 5.5-5 accept the same size cable but have a differently spaced fork!

How do you know which size you need?

Looking at the product code it basically tells you everything:

SV = fork crimp

5.5 = max cable size in mm2

5 = M size screw the opening is suited for

Examples:

- SV5.5-4

- Fork Crimp

- 5.5mm2 max

- M4 screw size

- which is perfect for all the barrier terminal boards

- SV5.5-5

- Fork Crimp

- 5.5mm2 max

- M5 screw

- which fits perfectly for the Power-7HC boards

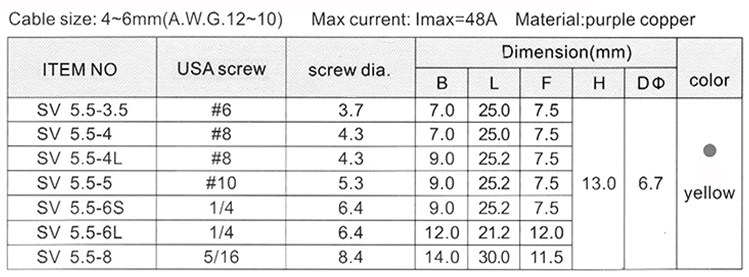

If you’d like to know for other cables sizes too, please see this version of the above table!

Extra example

You might want to use different size cables then the 10AWG or 12AWG I mentioned before (please make sure to use enough “copper” between your power supply and board!). As an extra example, if you had a 16AWG cable for instance and you want to connect to an M3 screw you’d use a SV 2-3 (SV for fork crimp, 2 for ~2mm2 cable, 3 for use with an M3 size screw).

The shop I’ve linked to has easy to use tables such as above for any type of cable and screw you might be looking for!

Not ring crimps?

An alternative which kind of look the same as fork style crimps are ring style crimps. My experience however is that ring crimps take up more room then a fork style and this means they are less good to use with a barrier terminal.

They are more suited for screws that have nothing besides them (like for instance on the QuinLED-Dig-Octa System Power-7HC, for that board you can use ring crimps such as the RV 5.5-5). If you want to connect an even thicker cable the 10AWG (recommend if you are truly running 100Amps continuous) it’s recommended to use a crimped on lug with an M5 hole.

You need a tool to attach these to your cable

To be able to crimp these fork/ring crimps properly you are going to need a crimping tool. I have one linked in my tools and equipment page here.

Special “double terminal” trick

Using fork crimps enables a special trick on some of my boards (QuinLED-Dig-Quad, QuinLED-Dig-Octa system Power-7(HC))! This trick allows you to basically use 2 output terminals at the same time and while these terminals aren’t designed to be used fork terminals, if you get the right fork crimp (It works best with the SV 5.5-5 or SV5.5-6 forks!) you can have one of the legs sticking in each terminal basically “doubling up” the output!

Using this trick you can connect a 10AWG or even 8AWG cable and since it’s also running over 2 fuses the maximum rated current is doubled from 10Amps max per fuse/output to 20Amps max!

This could be a good solution when you need to run a cable a really long distance and need the copper to reach that far without too much voltage drop. Also when you want to create a “bus bar” type of tap system instead of having all power wires be a home run it would also work perfectly for that!