QuinLED-Data-Booster-Maxi Power Injection

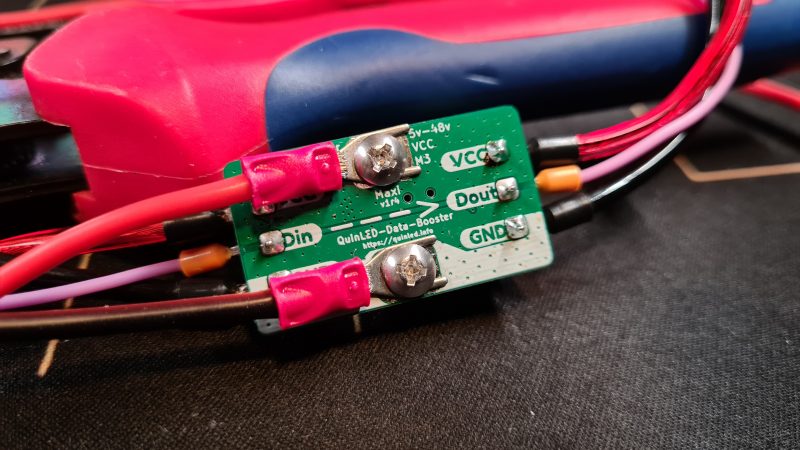

One of the features of the QuinLED-Data-Booster-Maxi is that you can use it for power injection, for this purpose there are 2 M3 sized plated holes on the PCB, one for positive and one for negative.

These holes can be used to solder a thick wire directly to those holes or you can use fork/ring style crimp on connectors and some M3 screws and locking nuts to be able to power inject between LED strips without having to solder anything!

It is recommended to use the forks/rings on the bottom of the board which has clear spacing for it!

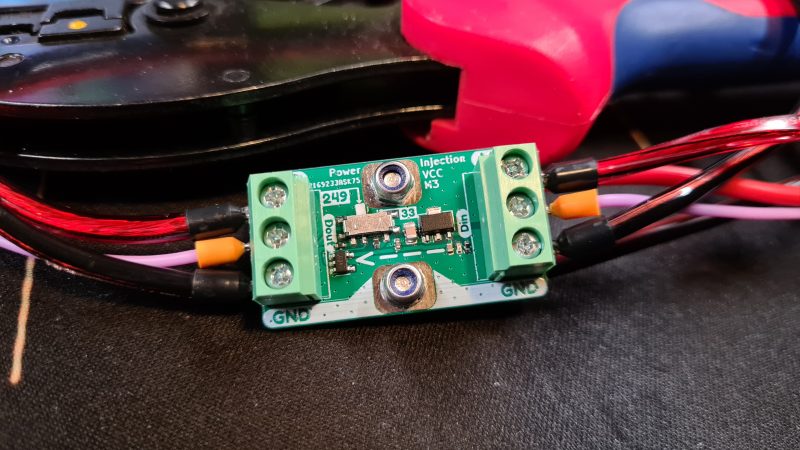

Front of the board showing all components and screw terminals

Recommended hardware

Tools:

![]() Ferrules crimping hardware (for use in the screw terminals)

Ferrules crimping hardware (for use in the screw terminals)

![]() Connector crimping tool (for crimping on connectors for M3 bolts)

Connector crimping tool (for crimping on connectors for M3 bolts)

![]()

Various size wires (Please watch my “Power Injection Livestream” to figure out wire size needed!)

Hardware: (A set of 2x M3 screws, nuts and fork crimp connectors is included in each purchase!)

![]() M3 Screws (6mm length recommended)

M3 Screws (6mm length recommended)

![]() Fork crimp connector (I recommend getting red and black so you can keep positive and negative apart easily!)

Fork crimp connector (I recommend getting red and black so you can keep positive and negative apart easily!)

(Sizes to get relative to cable thickness: SV1.25-3 or SV2-3 or SV3.5-3, most often the SV2-3 gives the best fit!)

Optional weather sealing:

![]()

Large diameter heatshrink (recommended size 16-18mm, the board is 22mm wide and 38.5mm long and about 10mm high)

(Fill remaining opening with hot glue)

Back of the board with wide spacing for fork/ring connectors!