New Fuses were needed

Back to QuinLED An-Penta Index

In the past the QuinLED boards have used ATO/Blade style fuses and sometimes auto-reset PTC fuses. But with technology moving forward new LED products have become available for both Analog and Digital boards using 36v or even 48v directly. Sadly the ATO style fuses I’ve used on many of my boards generally only support up to 32v. So, now what?

TL;DR

If you are just looking for a replacement fuse, check this article.

Auto-reset fuses? E-fuses? Evaluating different types of fuses

ATO fuse 32 volt limit

Generally available ATO fuses (Maxi, Mini or Micro) are only available with a max rating of 32v, while higher voltage models have become available these are prohibitively expensive to use and would make a product like the Dig-Octa powerboards jump to twice it’s current price. These fuses have also always been kind of big which have made fabricating them into a design with a case a hard exercise.

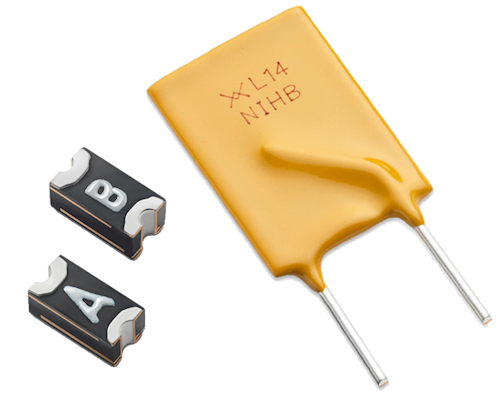

PTC Auto-reset fuses

In the search for a new fuse type to standardize on I looked into PTC (Auto-reset) fuses. I already use these extensively in my circuit design to implement protections for the onboard circuits. Sadly PTCs are less good in protecting larger loads, especially encased the amount of heat the PTCs generate quickly becomes an issue, also if you use multiple they start to react to each other can cause false trigger situations. As said, I still use PTC fuses in a lot of places and they will also be featured on some upcoming boards going but these are not the “end all”, usable in all place fuses in my opinion.

E-fuses

E-fuses are currently still expensive, especially if you need them in 48v+ range, next to that, especially at higher voltages, they are also limited in the amount of Amps they can support which then becomes a problem again at low voltages. They are are also quite expensive so again a Dig-Octa powerboard for instance would end up costing double to triple the current price easily.

Glass fuses, ceramic fuses

Another type of fuse that will support a high voltage are glass and ceramic fuses, the generally available models however are even bigger then the ATO size fuses, especially in regards to board real-a-state. They also have a fairly high resistance which in turn causes a lot of heat meaning they are not very suited for high Amp loads or enclosed products.

The new fuse type, “SMD Fuse” 1808 style

The fuses I ended up with, after lots of testing, are the SMD style fuses called an “1808” fuse. These can be had in various types such as slow-blow and fast-blow and support reasonably high voltages with the generic types supporting up to 125v. Depending on the type they can be found from 0.5Amp up to 20Amps fast blow or even up to 40Amps for the slow blow fuses!

My own testing concludes, resistance is key

If anything I am someone who tests things myself. And so after evaluating all of the above and testing some of them I reached the conclusion that SMD 1808 fuses are the best type going forward. I have tested both premium brands such as littelfuse and cheap options from Aliexpress!

To solder or not to solder, that is the question

During testing I discovered that these fuses indeed can work well and with low resistance (meaning little generated heat) but there differences if you used a premium socket or a cheaper option. Same goes for using a socket at all so either using a socket or soldering the fuse directly to the board. The fuses themselves didn’t seem to matter too much, so a fuse from littelfuse seems to act the same as various replacements and cheaper options I bought from Aliexpress.

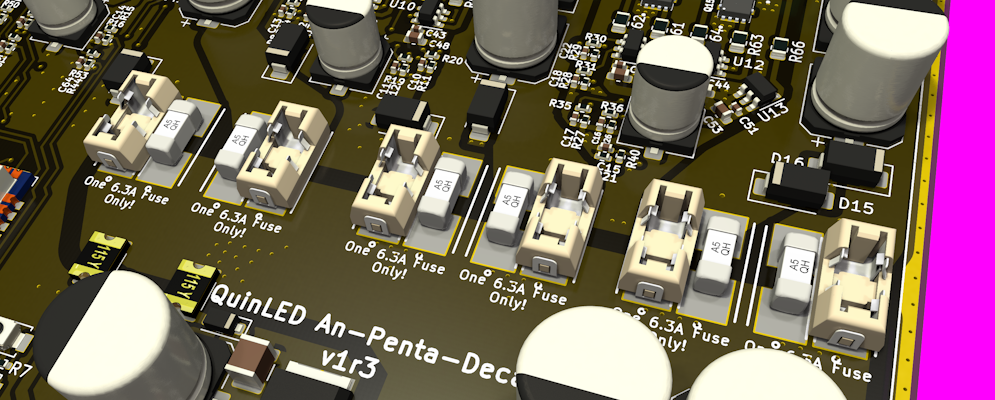

Both a socket and a fuse?

Some of my products going forward you will see with a pre-soldered fuse directly on the board AND a empty fuse socket. The reason for this is because the fuses soldered directly to the board have a lot less resistance and thus generate a lot less heat, especially if this a product that is housed in a case, this has the benefit of things not heating up so much. If however in the field the fuse does break (90%+ of customers never have to replace a fuse) you can easily just pop one in the socket next to the soldered one and you are back up and running again.

Even though this fuse will now run a little bit warmer then the others (I have tested that this does not affect product performance) it does mean the fuses can still be replaced without any soldering required.

Premium or cheaper model Fuse/Socket

As mentioned above I tested several brands of fuses and sockets, below are my conclusions.

In regards to the fuses themselves:

- I found little to no difference between original littelfuse models or some other brands or no-name bought of Aliexpress. Below you will find links to Aliexpress and Allnet!

- Aliexpress, Stores I have purchased samples from:

- Allnet, you can order them along with an order!

I did however find differences in the sockets, the cheaper sockets showed a higher resistance and thus generated a bit more heat vs premium sockets from Littelfuse so going forward most of my products will be integrating the premium socket.

End conclusion

Hopefully this articles explains a little bit why I went with this type of fuse. I know having to get another type of fuse will be kind of a bother but I strongly believe in having realistic value fuses in most if not all of my products. These fuses need to be fit for purpose and prevent your house or venue from burning down in the case something does go wrong.

There are hundreds of types out there but it’s always a bit of a balance of quality, price, resistance (heat), size and availability. I think with these new 1808 SMD fuses I have found the best fit for most of my products that need to support 48v! Thus the (currently) upcoming Analog boards will feature them and also the (currently) upcoming Diff-Adv series for instance! I will try and have a fuse replacement guide for all products that have a case!